With our Gas to Solid process, years of experience and certified quality assurance processes we can accommodate an extremely wide range of customers’ wishes and needs in the manufacture of components made of pyrolytic boron nitride.

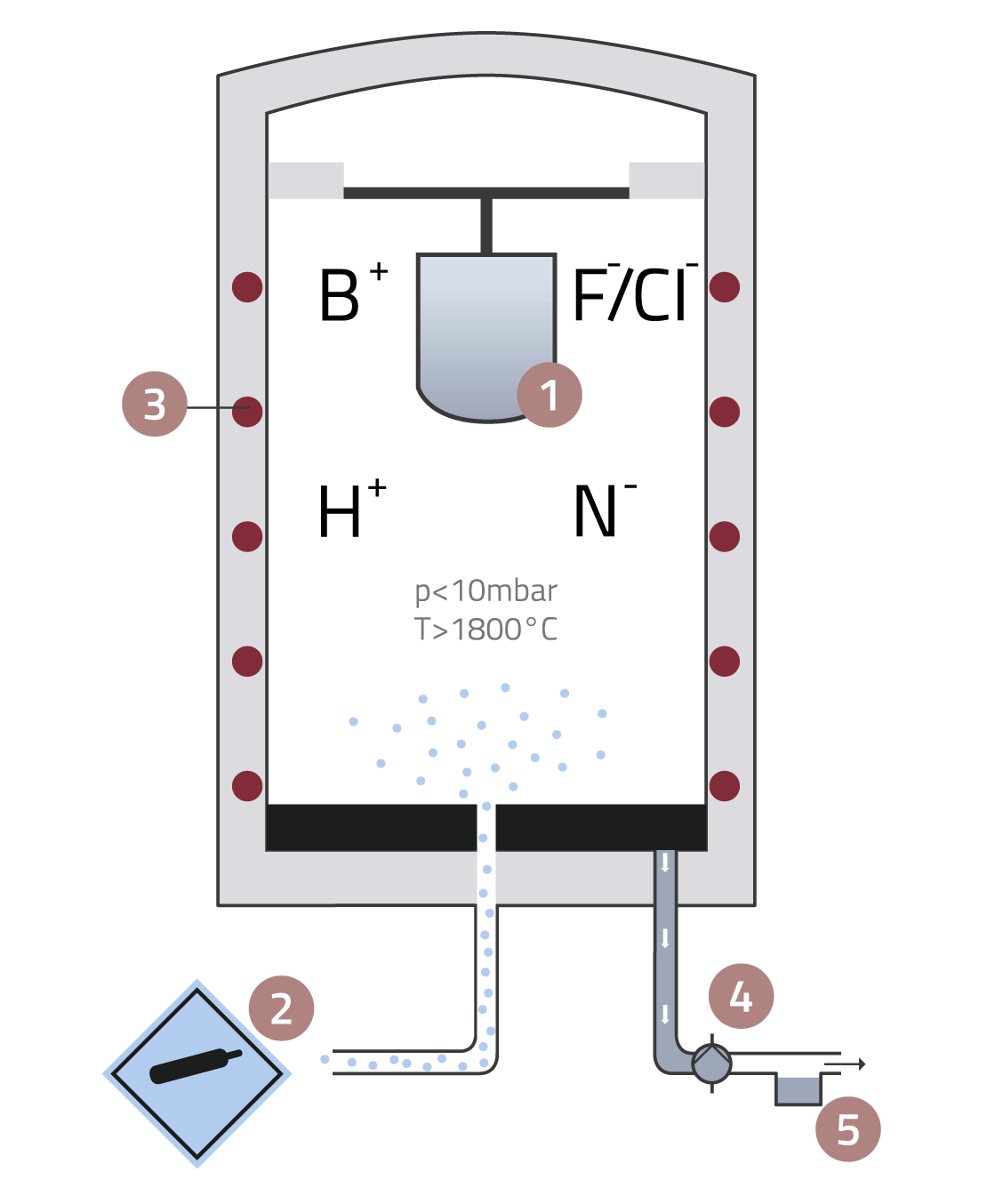

Gas to Solid means that, starting out from different gases, we vaporise these under vacuum at high temperature and deposit the gaseous components on a mould or a component as a solid (pyrolytic boron nitride/pyrolytic graphite) in extremely thin layers. In this way we can obtain the required solids from gas in the highest purity and equip these with individual properties.

In the CVD process we use highly pure gases such as boron halide (BF₃ and BCl₃), ammonia (NH₃) and nitrogen (N₂) or hydrocarbons.

These gases are brought to reaction at high temperature and coat the graphite mandrels installed in the reactor under a controlled atmosphere. This thin coating is applied to mandrels produced specially according to customers’ specifications. The form is determined by the graphite negative.

Depending on the type of graphite, the coating can be removed following the process (free-standing PBN component) or a coating is produced on the graphite (coating).

The surfaces of the components are then processed according to the customer’s specifications before these are cleaned, packed and then made ready for shipping.

Flexible, highly resistant, pure: the properties of CVT’s CVD products

The highest manufacturing standards are complied with in the manufacture of all of CVT’s products which are manufactured by means of Chemical Vapour Deposition. Only in this way can the products made of pyrolytic boron nitride or graphite fulfil the high requirements which apply when in use.