Nowadays, carbon components and composites are used for numerous high performance applications such as in the automotive industry, in aerospace and in numerous industrial applications. These need to be light, heat-resistant and extremely robust and fulfil very special technical requirements. Sometimes as one-offs, sometimes as mass-produced parts. With our patented r-CVI process (rapid Chemical Vapour Infiltration) we are able to manufacture the necessary parts quickly and economically and adapt them to your requirements.

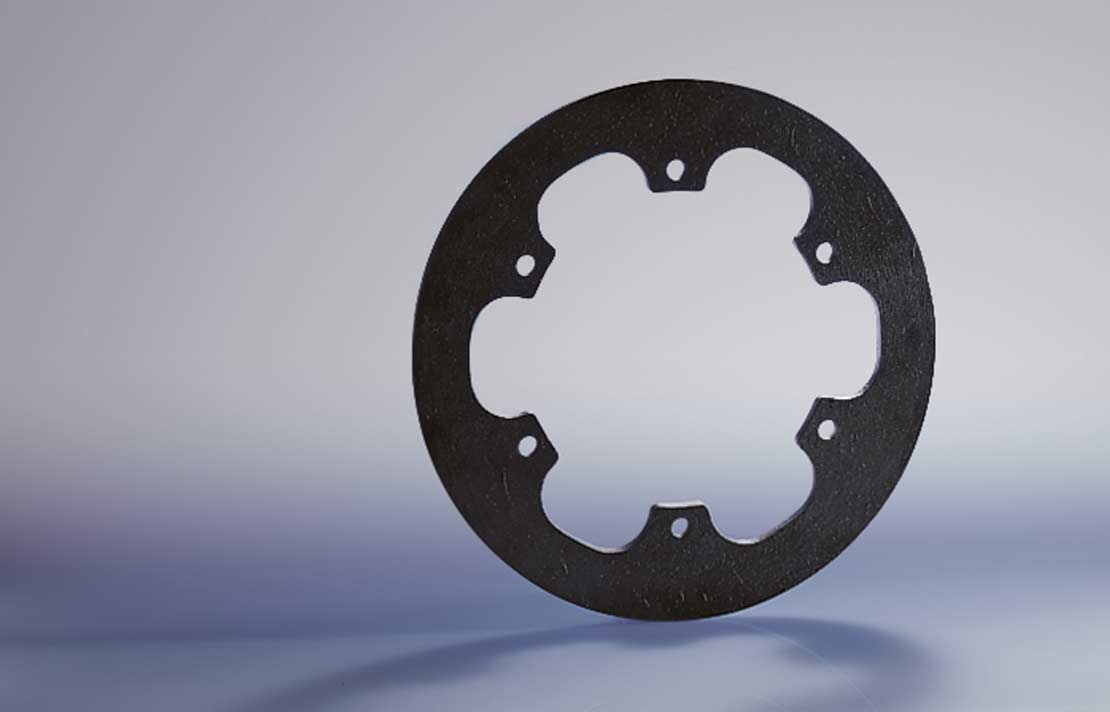

Brake discs and brake pads

When Formula1 racing cars are braked at full speed, this places an extreme load on the brakes and the parts subject to wear, in particular the ceramic brake discs.

With the aid of Chemical Vapour Infiltration we are able to make brake discs extremely tight and efficient. In cooperation with our partners, we are one of the leading manufacturers of brake materials for motor racing.

Nozzles and other C/C components

Due to their hardness, C/C components offer particularly good protection against abrasive wear, both under pressure and under friction loads.

We have made use of our experience in the development of brakes in order to develop further solutions to meet the diverse requirements of our customers by modifying the material to match the particular application - this allows us to create ideal conditions for a wide variety of different applications such as in the aerospace industry. Generally, the material is highly suitable for all applications in which a particular surface property is required under high temperatures.