CVI – Chemical Vapor Infiltration

In the Chemical Vapour Infiltration process, process gas is infiltrated into the existing structure (preform) and brought to reaction. In this way, carbon is deposited on the fibres in the interior of the preform. C/C structures can be adapted individually to the customer’s needs in such a way that these are significantly stronger and more heat-resistant following the r-CVI process than before. Among other applications, this technology is used in brake discs in Formula 1 racing cars, as well as in the aerospace industry.

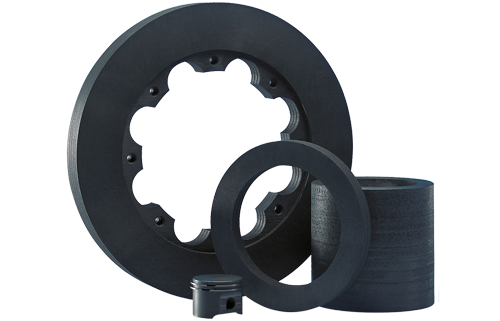

PRODUCTS

The brake discs, brake pads, nozzles and other carbon fibre carbon composite (CFC) components fulfil the highest standards for extreme applications.

With our patented Rapid Chemical Vapour Infiltration process (r-CVI) we offer the world’s fastest means of producing individual parts and prototypes using the CVI process. Through further treatments such as siliconisation, temperature-resistant and oxidation-resistant materials for rocket nozzles are being developed for the market in cooperation with, for example, Airbus Defence and Space and Airbus Innovation.